Z31 Z31 W-series Engine (or W-series Components)

In late 1987, Nissan changed the design of the VG30 engine, slightly, to provide a decrease in noise levels and an increase in power output. There is a lot of confusion as to what changes were actually made. This is a comprehensive listing of changes that were made to the VG30 engine.

Changes to the VG30 Engine (to create the W-series engine):

The major engine components that have been changed to create the "W" engine are shown below. In addition, a summary of changes is provided for each component.

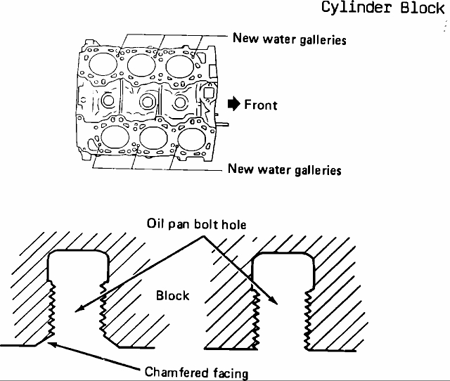

- Cylinder Block

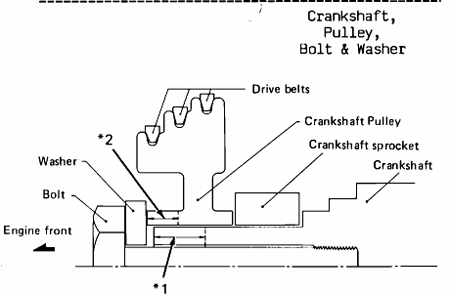

- Crankshaft, Pully, Bolt and Washer

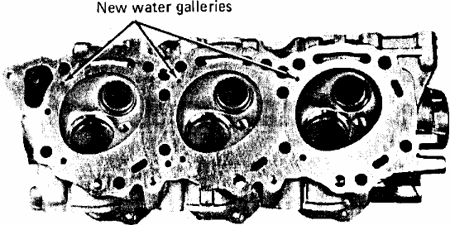

- Cylinder Head

- Cylinder Head Gasket

- Connecting Rod

- Piston and Piston Pins

- Interchange

W Series Block Information

Six new water galleries were added at the exhaust side of the cylinders. NOTE: The "W" engine bare block will NOT be stamped with a "W". Check for additional water galleries to identify a modified bare block.

In addition, the oil pan bolt holes have been altered in the modified cylinder block. The holes have been chamfered to allow usage of a liquid oil pan gasket. These chamfered bolt holes are also helpful in identifying the modified bare block.

W- series Crankshaft, Pulley, Bolt & Washer Differences

On the W-series motors, the crankshaft front tip was lengthened by 18.7 mm (0.736) in. See illustration (*1). The crankshaft pulley width was also increased by 13.6 mm (0.535 in.) as shown (*2).

The pulley bolt was changed from M12 to M14, and the washer inner and outer diameters were increased. (See illustration.)

You can use a non W-series pulley on the W-series crank but a spacer must be used. >Nissan part # 12308-V5321 was designed just for this purpose.

W-series Cylinder Head and Cylinder Head gasket Differences

Cylinder Head:

On the new W-series motors, three (3) new water galleries were added to each cylinder head (at the exhaust side). These match the new galleries in the block. (see below)

Cylinder Head Gasket:

Three new holes were added to the gasket on the exhaust side, and the six holes in the intake side of the gasket were decreased in size.

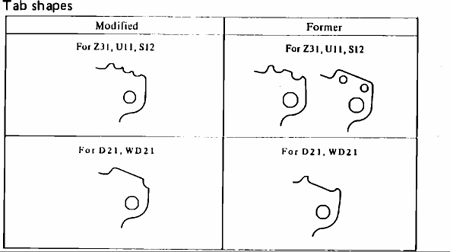

Cylinder Head Gasket Identification:

The tab shape can be used to identify the modified gasket from the non-modified gasket. (See illustration.)

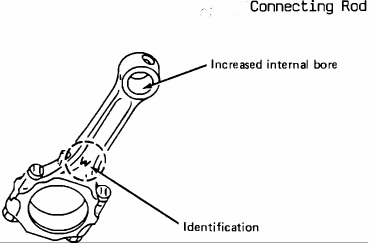

W-series Connecting Rod Differences

Connecting Rod:

The modified connecting rod has been increased in weight, along with an increase in small end internal bore. It can be identified by a "W" stamped in the side of the rod shaft as shown in illustration. NOTE: A "W" connecting rod requires a "W" piston, new style wrist pin, and modified crankshaft.

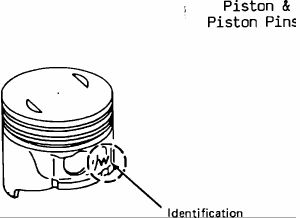

W-series Piston and Piston Pin Differences

PISTON & PISTON PINS:

In the W-series motors, the piston and piston pin have been changed to a full-floating type, with two snap rings to locate the piston pin. Also, piston pin outer diameter has been decreased. The modified piston can be identified by a "W" mark on the piston skirt (As shown). NOTE: A "W" piston requires a modified connecting rod, wrist pin, and piston rings.

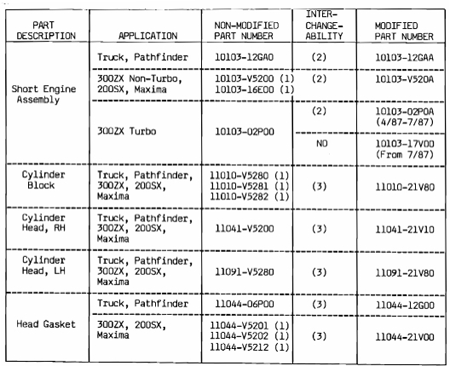

Interchange

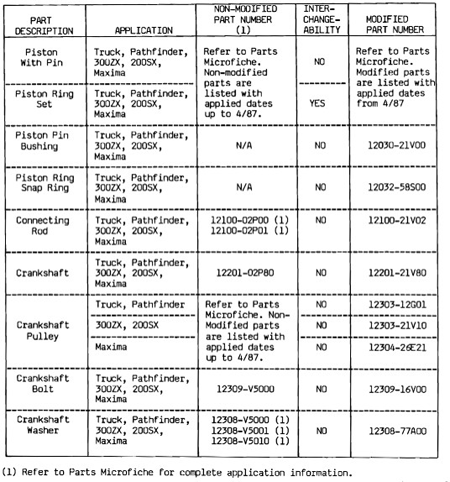

In certain combinations, some MODIFIED engine components can be installed on NON-MODIFIED VG30 ENGINES (production prior to April, 1987) as shown in the following chart. However, NON-MODIFIED ENGINE COMPONENTS CANNOT BE INSTALLED ON MODIFIED VG30 ENGINES (production starting April, 1987).

Use the chart below to determine proper component combinations.

- Refer to Parts Microfiche for complete application information.

- Modified short engine can be used in place of non-modified short engine in conjunction with the cylinder head/head gasket combinations shown as acceptable in chart on page 4/6. Also, the crank pulley must be changed as indicated below:Truck, Pathfinder, 200SX, Maxima, and 300ZX (except 300ZX prior to 9/86 production), must use the modified crankshaft pulley, bolt and washer shown in the chart on page 6/6.

300ZX Non-Turbo prior to 9/86 production requires crankshaft pulley (P/N 12303-12G01, bolt (P/N 12309-16V00) and washer (P/N 12308-77A00). 300ZX Turbo prior to 9/86 production requires crankshaft pulley (P/N 12303 5320), spacer (P/N 12308-V5321), bolt (P/N 12309-16V00) and washer (P/N 12308-77A00). - Modified parts can be used in place of non-modified parts in combinations shown as acceptable in chart on page 4/6.