Replacing Front Struts on your 280ZX

The following text describes what I did to my car, and how I overcame the problems I ran into; it is for discussion purposes only and should not be construed as instructions for how to do this to your car. If you want instructions, get the factory service manual; it really is very good.

I wrote these notes so that if I ever need to do this again I'll have something to help me remember what I did, the order I did it in, what problems I had, and how I solved them. Since I had it all written, I thought others might find it interesting. Perhaps those who are contemplating doing this might gain some idea of what is involved, but do not think of these notes as instructions. If you attempt to duplicate what I did and injure yourself or others, I am not responsible. You have been warned.

I did everything by myself with the exception of reinstalling the struts onto the car. I had a friend help guide the tops of the struts into the mounting holes, which was a real help.

Background

I actually had to make two separate attempts to do this job. The first time, I got everything off the left side, removed the coil spring and upper mounting bearing, but could not get the gland packing nut loose. My main problem was that I did not have the strut bolted to something solid — a buddy of mine was trying to hold it while I loosened the nut. Unless you have a cooperative, fully grown mountain gorilla to hold the strut, that won’t work (and probably not even with a gorilla).

Second Attempt & Solution

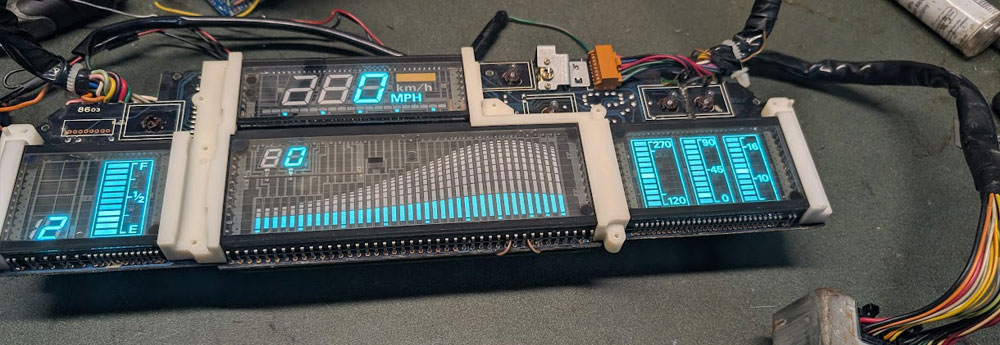

Before the second attempt, I bought two 6-inch long, ¼-inch bolts with washers (two washers per bolt) and nuts to bolt the strut to a spare 6-foot section of 6×6 landscape tie I had on hand. This required drilling 5/16-inch holes at 3⅛ inches apart, counterboring one side so the heads and washers would sit deep enough for the bolts to fit through the strut’s bottom holes.

With the strut mounted like this, getting the coil spring compressor on was much easier, and removing the gland packing nut was straightforward with a 14-inch pipe wrench. Mounting the strut also made handling the old insert cleaner — I only had to unbolt it to pour the oil into a prepared plastic bottle.

Final Thoughts

I’ve broken the job into discrete tasks with several steps each in my notes, but I’ve left out some simple details and included more about the problems and solutions. For the full procedure, see the factory service manual.

*WARNING* - Do this diagnosis/mods at your own risk. We Are not responsable for any issues of your own doing.

Preliminary preparations

-

Purchase all of the parts you want to replace. I replaced:

- Strut inserts (Tokico Illuminas)

- Upper strut mounting bearings

- Lower ball joints (only ball joints on the car)

- Outer tie rod ends

- Strut dust boots and bump stops

- Tension rod bushings (don’t forget new self-locking nuts)

- Stabilizer end link and mounting bushings (also get new self-locking nuts)

This would have been a great time to replace the front wheel bearings, brake rotors, calipers, and pads, but I wanted to finish in one weekend. When reinstalling:

- Wheel bearing dust caps → new O-rings required

- Wheel bearing nuts → new cotter pins required (I used 1.5-inch zinc cotter pins)

Everything except the Tokico inserts, dust boots, and polyurethane bump stops came from Nissan — excellent quality, and the ball joints/tie rod ends included castle nuts and cotter pins.

- Get a dozen quart-sized zipper freezer bags (I used GladLock, but any brand works). Label six of them LEFT and six RIGHT with a permanent marker. Use these to store brake pads, wheel bearings, etc., so they stay clean and can be reinstalled on the correct side.

-

Make sure you have the special tools you’ll need:

- Coil spring compressors

- Ball joint/tie rod separator (I used pickle forks since I was replacing them)

- Big hammer (for the pickle forks)

- Large screwdriver (to separate the strut from the steering knuckle/lower ball joint)

- Torque wrench (25–100 ft-lb range)

- 18-inch breaker bar

- Have something solid to mount the strut on before loosening the gland packing nut. There’s a special socket for this nut, but I just used a pipe wrench.

Prepare the Car and get Access to the Parts to Replace

- Loosen front lug nuts ½ turn.

- Jack up the car and support the front on jack stands (refer to the factory service manual or Haynes manual for jack points and stand placement).

- Remove front wheels.

-

Remove brake calipers and suspend them on spare jack stands.

Avoid mangling, kinking, or stretching the brake hoses.

Note: The Haynes manual advises disconnecting the brake hose and plugging it — this mainly applies to ’82 and earlier models with the hose support clip on the strut. My ’83 lacks this clip, so I left the hose connected. If you do disconnect the hose, be sure to bleed the brakes properly during reinstallation.

- Remove brake pad retainers and brake pads. Store them in the labeled bag for their side of the car.

- Remove brake caliper mounting brackets.

- Remove wheel bearing dust cap and store in a labeled bag. Do not store it with brake parts.

- Remove the cotter pin (discard it), then remove the wheel bearing nut cap, nut, washer, and bearing. Store them together in their own labeled bag.

- Remove wheel hub/brake rotor assemblies. Tip: I stored mine in cardboard boxes along with their labeled bags and set them aside in the hatch until reinstallation.

- Clean the spindle — not strictly necessary, but it prevents old grease from getting everywhere.

-

Remove deflector shields.

Problem I had: The four Phillips screws were extremely tight after nearly 15 years. Solution: Using a screwdriver with interchangeable bits, I gently tapped a #3 Phillips bit into the screw head, then used a 3/8" ratchet with a 6" extension and ¼" socket to turn the bit. Credit to Marshall Cone of ZCCNV for this trick — it worked perfectly.

- Loosen all lower bolts ½ to 1 turn:

- Tension rod to control arm

- Ball joint to control arm

- Steering knuckle to strut

- Tie rod adjustment lock nuts

- Outer tie rod castle nut (remove cotter pin first)

- Loosen all upper strut nuts ½ turn:

- Strut insulator mounting nuts

- Piston nut (only ½ turn)

Bushings, Ball Joints, and Tie Rods

- Remove tension rod to front mount nut (bushing nut) and withdraw tension rod from the front mount.

- Separate tie rod ends from steering knuckle.

- Remove tie rod ends from steering rack, holding the threaded part so it does not turn (use an open-end or adjustable wrench on the flats). Count the turns required to remove the outer tie rod end. Swap grease fittings to new tie rod ends, or preferably use new fittings.

- Install new tie rod ends onto steering rack, turning them the same number of turns as removal.

- Install tie rod end into steering knuckle. Incrementally torque the castle nut, checking alignment with the cotter pin hole. Install new cotter pin and tighten tie rod adjustment lock nuts, again holding the flats on the threaded part.

-

Remove steering knuckle-to-strut bolts.

Issue: On the right side, one bolt was so tight that I broke the drive square on a ½" to ⅜" socket adapter. Fix: Used a 6-point Craftsman box wrench, sat on the asphalt, and pushed with my foot. Took three 60° pushes before loosening enough to turn by hand. Threads were fine, so I reused it.

- Remove strut mounting insulator nuts (three nuts securing the strut mount to the hoodledge — NOT the strut piston nut).

-

Remove strut and spring assembly and set aside for rebuild.

Use a large screwdriver to pry the strut loose from the steering knuckle, then pry down on the control arm/knuckle/ball joint enough to remove the strut.

The strut assembly is heavy (~50 lbs), so maintain a stable squatting or kneeling position and keep a firm grip.

- Remove cotter pin and castle nut from lower ball joint. Keep ball joint/tension rod bolts in place during removal to avoid deforming the control arm.

- Separate lower ball joint from steering knuckle.

- Remove lower ball joint mounting bolts and remove lower joint. Swap grease fittings to the new ball joint or use new ones.

- Install new lower ball joint to control arm, but only install the inner (short) bolt for now.

-

While tension rod bolts are out, install new tension rod bushings with new self-locking nuts.

Tip: With the struts out, lay the control arm end of the tension rods on top of the control arm so the rod is nearly orthogonal to its front mount. Clean rust and rubber from the bushing caps and frame to allow enough thread engagement for the nuts to start by hand.

- Install tension rod mounting bolts (thread through the lower ball joint via the control arm).

- Install stabilizer bar end link and mounting bushings. Remove the front lower shield under the engine to access stabilizer mounting brackets. Torque all stabilizer nuts and bolts to spec, then reinstall the lower front shield.

- Install lower ball joint into steering knuckle.

- Incrementally torque the ball joint castle nut, checking alignment with the cotter pin hole. Install cotter pin when torque is correct and the hole aligns with a nut slot.

- With struts out, the stabilizer bar can hold control arms so that tension rods are nearly orthogonal to their mounts. Since a torque wrench with 17mm socket wouldn’t fit inside the mount, I used a 17mm open-end wrench to snug the nuts until they bottomed against the bushing spacer. (Not factory procedure, but it worked in my case.)

Rebuild Struts

-

Using the two holes in the bottom of the strut where it attaches to the steering knuckle, bolt the strut to something solid.

My setup: A 6 ft. section of 6×6 landscape timber with two 5/16" holes drilled 3⅛" apart and counter-bored 2" deep. Quarter-inch × 6" bolts went through to secure the strut.

- Detach the bottom of the old strut boot from the top of the housing by spreading the lower boot clip.

- Compress the coil spring using spring compressors per manufacturer’s instructions.

- Once the spring is loose in its seat, remove the old strut piston nut (should be easy if loosened earlier).

- Remove the upper mounting insulator. The bearing may come with it or stay on the lower half — note orientation for reassembly. Clean the mounts and bearing dust cover.

- Remove the lower half of the mount with the old boot and bump stop. Replace with new boot and bump stop, matching the original orientation (flat side toward mount, rounded toward housing). Transfer the lower boot clip to the new boot.

- [Optional but done here] Remove the coil spring with compressor still attached and store safely away from the work area.

-

Remove the gland packing nut with a 14" pipe wrench, being careful not to damage the housing.

My bolts bent slightly from the force, but they were cheap (86¢ total) so I didn’t mind replacing them.

- Remove the rubber seal under the gland nut using a pick tool.

- Slowly remove internal strut components. Avoid spilling the oil inside — then unbolt and pour it into a jug for proper disposal.

- Rebolt the housing to the mount and install new Tokico Illumina inserts. Shake gently to seat fully. Tokico recommends a light oil bath; I reused the old oil, as the insert nearly fills the housing.

- Grease the sealing surface of the new gland packing nut and washer, then carefully install without scratching the piston.

- [If spring was removed] Recompress coil spring.

- Seat the coil spring in the lower perch and install the lower half of the upper mount with boot, bump stop, and clip onto the piston.

- Install upper strut mount bearings (new or reused) and bearing dust covers.

- Install the top part of the upper mount and thread on the new self-locking piston nut (remove protective rubber cover first). Hand-tighten for now; final torque will be done on the car.

- Slowly release the spring compressor, ensuring the spring seats properly at both ends.

- Spread the lower boot clip, slide the boot over the housing top, then secure the clip.

- Unbolt the rebuilt strut from the solid mount — it’s now ready for reinstallation.

Reinstall Struts, Shields, Hubs, and Brakes

- Reinstall struts — apply sealant to the steering knuckle mating surface. Insert the upper insulator bolts into the hoodledge holes. Tip: A helper can guide the bolts from above while you position the strut below. Have them start the washers and nuts once the bolts are through.

-

Lever the bottom end of the strut over the ball joint castle nut and into the steering knuckle using a large screwdriver or pry bar.

My helper pushed down on the tension rod just ahead of the control arm while I levered the strut into place.

- Install and torque the bolts connecting the steering knuckle to the strut bottom.

- Torque the tension rod mounting bolts to specification.

- Torque the upper strut mounting nuts and the strut piston nut.

- Install the deflector shields back onto the strut housing.

- Repack the outer wheel bearing, then install the wheel hub/brake rotor assembly, wheel bearing, washer, and castle nut. Follow the FSM procedure for adjusting the wheel bearing preload. Install the nut cap, cotter pin, and a new o-ring on the dust cap before fitting it.

- Install the brake caliper bracket, brake pads, pad retainers, and caliper. Torque all fasteners to factory specifications.

Reinstall Wheels and Lower Car, Clean Up and Alignment

- Install the wheels and snug the lug nuts by hand.

- Lower the vehicle carefully off the jack stands.

- Torque the wheel lug nuts to the factory specification.

- Put away all tools, jack stands, and other equipment.

- Schedule and complete a professional alignment before driving too far. Note: This is required any time tie rod ends or tension rods are removed or replaced.

Sources Used

- Original Article by Andy Anderson

- 1979-1983 280ZX Nissan Factory Service Manuals